Customer Stories

Imuraya USA was established in 2009 in Irvine, California, with the vision of bringing Japanese flavors to the global market. Using production and quality control techniques from Japan, the company manufactures and sells frozen Japanese-style sweets and desserts, particularly those using azuki (red bean)—a core ingredient of its parent company in Japan.

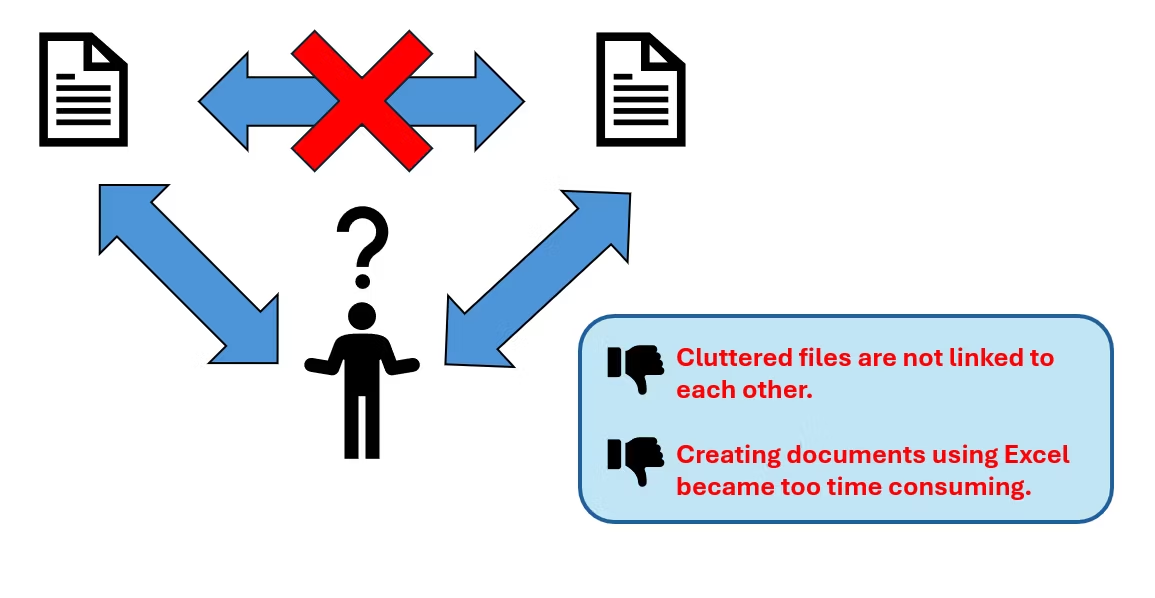

Imuraya USA was managing product information, raw materials, and quality inspection records across various Excel, Word, and PDF files stored on a shared server. As the number of products and supplier base grew, the folder-based system became difficult to manage – slowing down searches, increasing risk of errors, and making collaboration across teams inefficient.

Both teams were often rewriting or duplicating similar information in different documents, further reducing efficiency.

The Imuraya team wanted a platform that could centralize and organize its documents while making it easier to search and connect across departments.

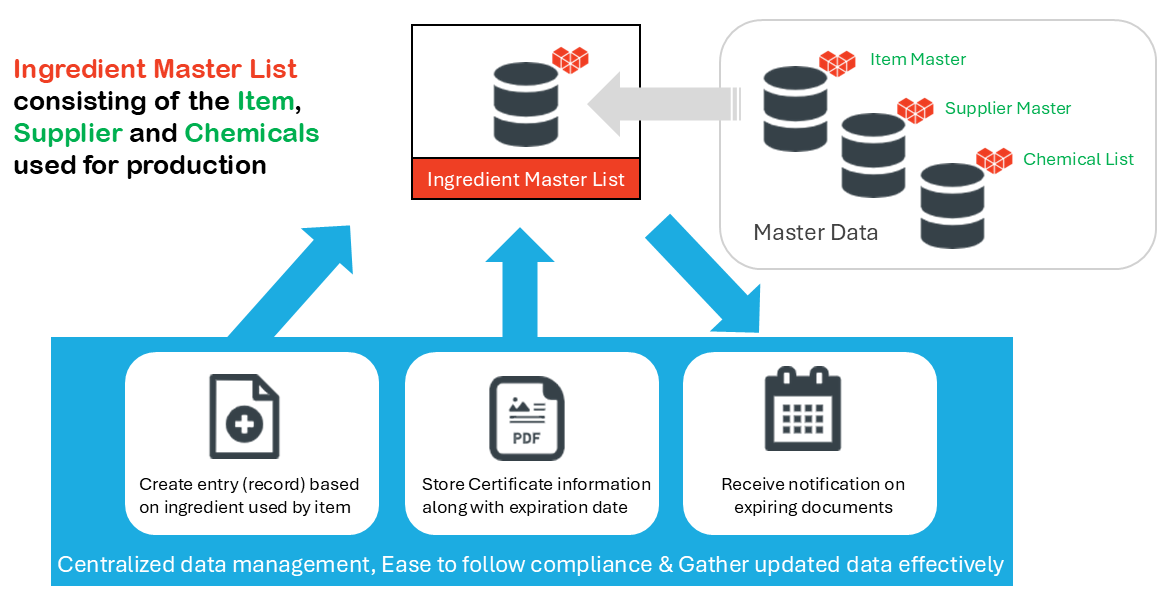

One key consideration was maintaining compliance with SQF (Safe Quality Food) certification, which requires proper management of product and raw material specifications, as well as quality assurance records.

They evaluated other platforms but found them too narrowly focused on food safety. Kintone stood out because it allowed them to:

With Kintone, the Imuraya team transformed how information is managed across departments – shifting from scattered folders and forms to a centralized, accessible platform.

The Imuraya team plans to continue developing helpful apps within Kintone to further improve work efficiency across departments.

Interview Date: April 29, 2024

A digital integrator in the 5G era

Kintone Product Introduction Video